Welcome to our company

📧sales@artificialcasing.cn 📞+86 532 85663688

Foreign Research Progress Of Collagen Casing

Foreign Research Progress Of Collagen Casing

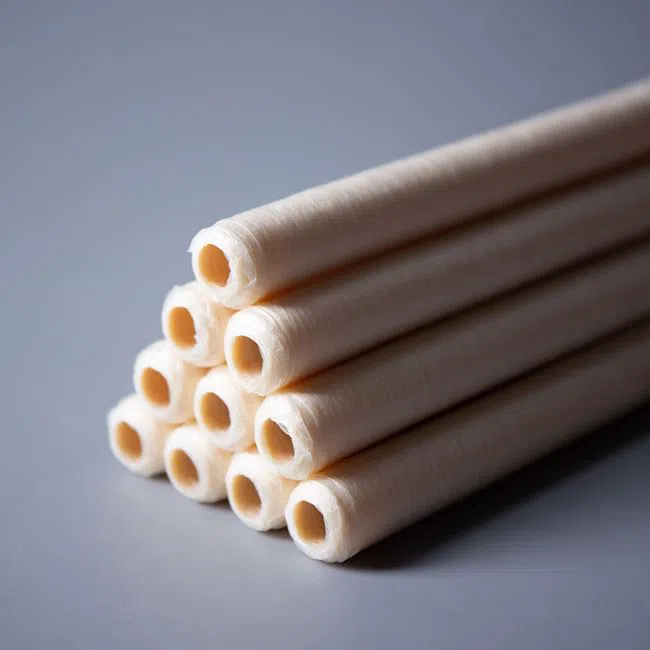

Starting in the 1930s, the United States and the United Kingdom began to study collagen casings; in the 1940s, Germany was able to produce collagen casings, but it could not tolerate high-temperature cooking. Later, Japan, the former Soviet Union, and the former Czechoslovakia invested a lot of effort. ; By the 1970s, the United States, the Federal Republic of Germany, Japan, Poland and other countries have been able to industrially produce high-quality collagen casings, and their production equipment has also become mature. my country has always been a major exporter of natural casings, and at the same time it imports a large number of artificial casings.

After years of research in the United States, Britain and other countries, it has been found that once collagen is transformed into gelatin, the physical and chemical properties and rheological properties of the material will change greatly and cannot be used to make casings. On the one hand, the strength of the casing cannot meet the requirements. The aspect is not resistant to cooking. Later, it was determined that the dermis layer of cowhide was used to prepare collagen paste to make casings. Of course, it has also been proved that the collagen-gelatin material can be used to make tubular casings. The wet tensile strength of the membrane made of dispersed collagen and a certain amount of hydrolyzed collagen can reach 17MPa and the elongation rate is 35%.

In recent years, some foreign collagen casing factories have added multivalent ions (such as Ca2+, which can coagulate collagen) and cross-linking agents into the acidic paste, and then extruded into the alkaline coagulation liquid. The casing has better cross-linking effect than the later stage, because the multivalent ions and cross-linking agent inside the paste will not solidify the paste, and once it enters the alkaline medium, the cross-linking agent is activated. The casing can be quickly cross-linked and solidified to obtain good strength. However, this kind of wet casing also contains 90% moisture and is not easy to dry. If it is completely frozen at -20°C for 5 hours and then slowly thawed naturally, 80% of the moisture can be removed and it has higher strength.

LATEST NEWS

- Pros And Cons Of Collagen Casing 2021-12-09 08:40:37

- Definition Of Collagen Casing 2021-08-20 11:38:53

- Definition And Use Of Casing 2021-06-09 11:47:11

- Casing Use Storage Method 2021-06-03 11:47:34

- Useage Of Collagen Casing 2021-05-13 11:48:54

- Introduction Of Collagen Casing 2021-05-11 11:48:02

- How To Produce Collagen Casing 2021-04-28 17:04:39

- Advantages Of Collagen Casing 2021-04-23 11:49:57

- Eligibility Criteria For Collagen Casing 2021-04-15 11:50:20

- Processing Technology Of High Quality Pig Casing 2021-03-26 11:45:29

Online Inquiry

Online Inquiry

Online Inquiry

Online Inquiry