Welcome to our company

Welcome to our company

📧sales@artificialcasing.cn 📞+86 532 85663688

Company Profile

青岛爱福肠衣有限公司

Qingdao Artificial Casing Co., Ltd

Qingdao Artificial Casing Co., Ltd. is located in Qingdao, which has the most important seaport of China-Qingdao port. We’ve two factories in Shandong province and an exporting company in Qingdao city. We are the professional supplier of artificial casings for years. Our main products include collagen casings and cellulose casings. After several years’ research and development, our products had served many customers from all over the world and won good reputation. The casings had been exported to many countries, such as USA, Germany, Denmark, Russia, Indonesia, Malaysia, Brazil, Peru, etc., and we will go on ...

6

Manufacturing Depart

12

Letters Patent

20

Industry Experience

1000

Cooperative Client

5000

Plant Area

Products

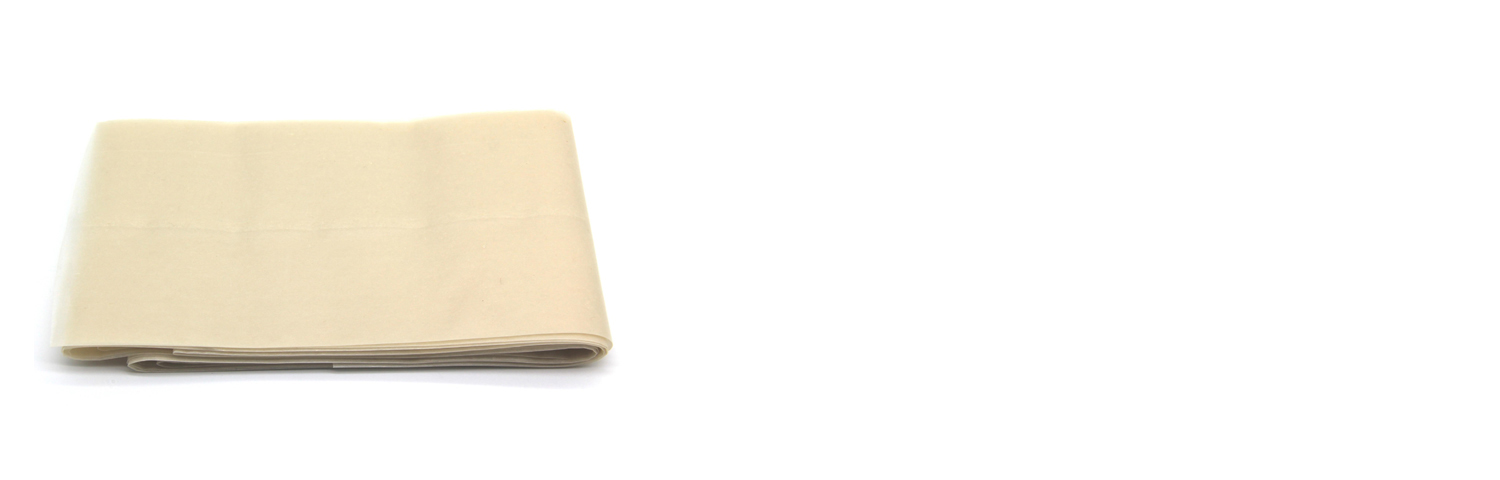

Our collagen casings are made from high quality cattle skin collagen fibers, with machines imported from USA, Germany, Poland and our patented technology, our Collagen Casings can offer outstanding performance to the sausage manufacturers in terms of consistency....

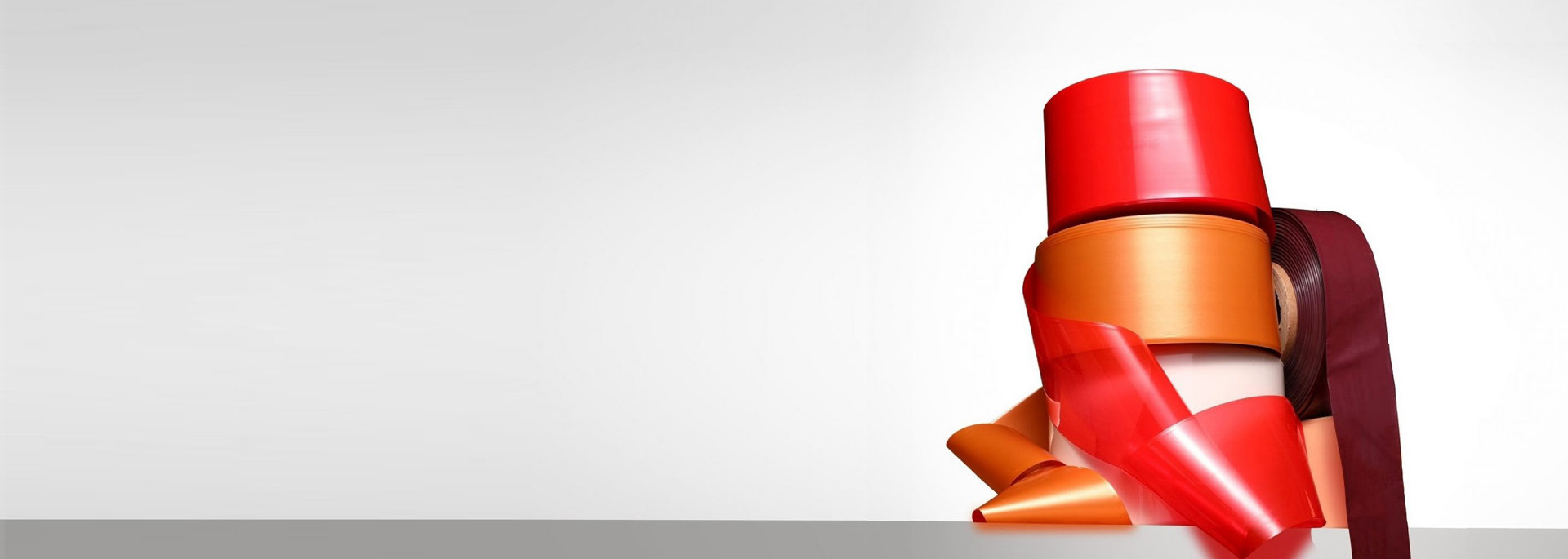

Our fibre-reinforced cellulose casing is of exceptional quality because it is manufactured using a special viscose process, which allows for smoke permeability and high mechanical strength. Fibrous casings are available in piece, shirred, or reel stock...

Our casings are used for a wide range of meat sausages and also for dairy products. All of our products passed industrial toxicological tests, heavy metal content, GMO and allergens tests with excellence. We have ISO, HALAL, CE and HACCP certificate....

Uniform thickness, high strength, good elasticity, good abrasion resistance, no static electricity, suitable for high speed automatic filling requirements.

Cellulose molecules have high permeability to water, air, and smoke, improving the sausage flavor and color.

Advantage

Customer Feedback

Products Applications

Online Inquiry

Online Inquiry